If you’ve ever wondered how magnificent structures, sturdy vehicles, and intricate pieces of machinery are born, the answer lies in the sparks of the welding torch.

Particularly, it lies in the world of arc welding, a captivating and vital process that’s been at the heart of metalworking for over a century.

From towering skyscrapers to the very car you drive, arc welding has played a crucial role. But what exactly is arc welding?

What different techniques are under its umbrella, and how do they each work?

Understanding the Fundamentals of Arc Welding

Arc welding is a process that uses an electric arc to melt and fuse metal work pieces together.

It’s a technique that has been used for over a century, proving its reliability in a variety of industries, from construction and shipbuilding to automotive repair and manufacturing.

In its basic form, arc welding involves creating an electric circuit between the welding machine and the work piece.

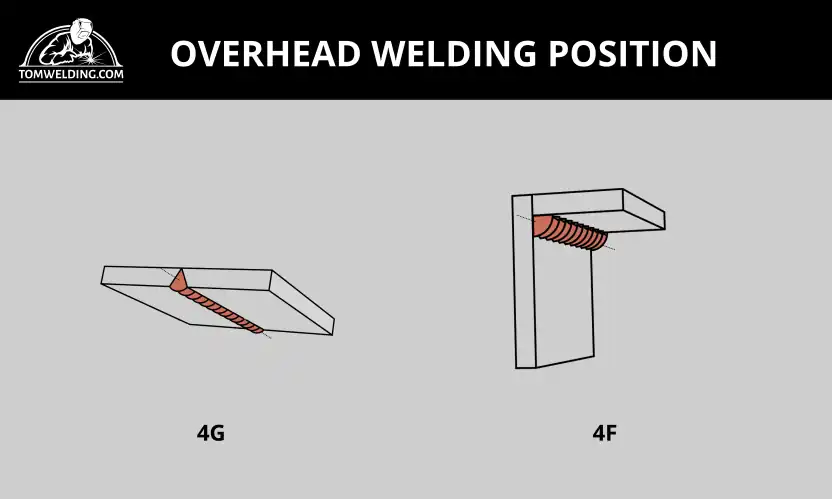

You also need to understand basic welding position

The power source generates a voltage, which helps create an electric arc when the electrode (usually coated in a flux) touches the work piece and is then pulled away.

This arc generates intense heat, melting both the electrode and the work piece, creating a pool of molten metal (weld pool) that solidifies to form the joint.

Different Types of Arc Welding

Over the years, various techniques have been developed to optimize and specialize the arc welding process for different applications. Here are some of the most common:

Shielded Metal Arc Welding (SMAW)

Often called stick welding, SMAW is one of the most used types of arc welding, especially for outdoor applications and repair work. It uses a consumable electrode coated in flux, which provides a gas shield to protect the weld pool from contamination.

Gas Metal Arc Welding (GMAW)

Also known as MIG (Metal Inert Gas) welding, GMAW uses a continuous wire electrode and an external shielding gas. The shielding gas, often a mixture of argon and carbon dioxide, protects the weld pool from contamination. It’s versatile, quick, and popular for automotive work and fabrication.

Gas Tungsten Arc Welding (GTAW)

Also known as TIG (Tungsten Inert Gas) welding, GTAW uses a non-consumable tungsten electrode and an external shielding gas, typically argon. It allows for very precise, high-quality welds, making it popular in industries requiring high-quality finishes like aerospace or pipe welding. It can weld a wide range of metals, including aluminum.

Flux-Cored Arc Welding (FCAW)

FCAW is similar to GMAW but uses a special tubular wire filled with flux instead of a solid wire. This flux provides the shielding gas, making this technique more suitable for windy outdoor conditions.

Submerged Arc Welding (SAW)

In SAW, the arc is submerged beneath a blanket of granular flux, protecting it from contamination and reducing ultraviolet and infrared radiation. It’s typically automated and is often used in industrial applications for high production rates.

Plasma Arc Welding (PAW)

PAW uses a constricted arc or a plasma jet to create a more focused and controlled heat source. It is often used for precision applications requiring deep and narrow welds.

Carbon Arc Welding (CAW)

In CAW, a carbon electrode is used to generate the arc, often in conjunction with a filler metal. It was once common, but has been largely replaced by other methods.

Arc Spray Welding

Arc spray welding, or arc spraying, is a form of metal spraying where two consumable metal wires are fed into an arc. The heat from the arc melts the wires, and an atomizing gas sprays the molten metal onto the workpiece.

Tackling Arc Welding Challenges

Like all welding techniques, arc welding has its challenges. One common issue is “arc blow,” where the magnetic field around the arc forces it out of the weld area. This can be managed by adjusting the welding parameters or changing the electrode’s direction of travel.

Essential Arc Welding Equipment

A typical arc welding setup consists of a power supply, an electrode holder, a ground clamp, and welding cables. Personal Protective Equipment (PPE), including a welding helmet, welding gloves, and protective clothing, is also crucial for safety.

A Glimpse at Arc Welding Diagrams

Understanding an arc welding diagram can greatly improve your welding skills. It typically shows the power source, electrode, work piece, and the flow of current, which can be either alternating (AC) or direct (DC). These diagrams often include the shielding gas or flux, the weld pool, and the direction of welding.

There you have it: a deep dive into the world of arc welding. It’s a vast field, one that requires constant learning and practice. But with a solid foundation, you can achieve great things in your welding career. Happy welding!