Welding is an essential skill in various industries, from construction and automotive to aerospace and manufacturing. It involves joining two or more metal pieces together using heat, and sometimes pressure or filler materials.

Welding Process

Before we get started, let me give you an overview of the most common welding processes we use:

- Stick Welding (SMAW): Stick welding, also known as Shielded Metal Arc Welding, uses an electrode coated in flux to produce an electric arc between the electrode and the base metal. The flux creates a protective gas shield and a slag layer, which protects the weld from contamination.

- MIG Welding (GMAW): Metal Inert Gas Welding, or Gas Metal Arc Welding, is a versatile process that uses a continuous wire electrode fed through a welding gun. An inert shielding gas, such as argon or carbon dioxide, is used to protect the weld pool from contamination.

- TIG Welding (GTAW): Tungsten Inert Gas Welding, or Gas Tungsten Arc Welding, is a precise welding process that uses a non-consumable tungsten electrode and an inert shielding gas, like argon, to protect the weld. TIG welding can be performed with or without a filler metal, depending on the application.

- Flux-Cored Arc Welding (FCAW): This process is similar to MIG welding but uses a tubular wire electrode filled with flux instead of a solid wire. The flux provides the necessary shielding, eliminating the need for a separate shielding gas.

Tips for New Welder

As a new welder, it’s essential to familiarize yourself with safety precautions. Always wear appropriate personal protective equipment (PPE), such as a welding helmet, gloves, safety glasses, and protective clothing. Make sure your work area is well-ventilated and free of any flammable materials.

Before you begin welding, it’s crucial to understand the properties of the metals you’ll be working with and the appropriate welding process for each application. Proper joint preparation, including cleaning and beveling, is also essential for achieving strong, durable welds.

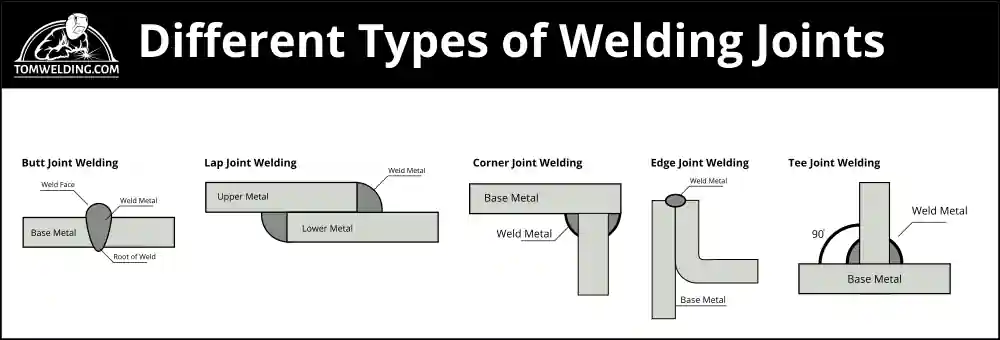

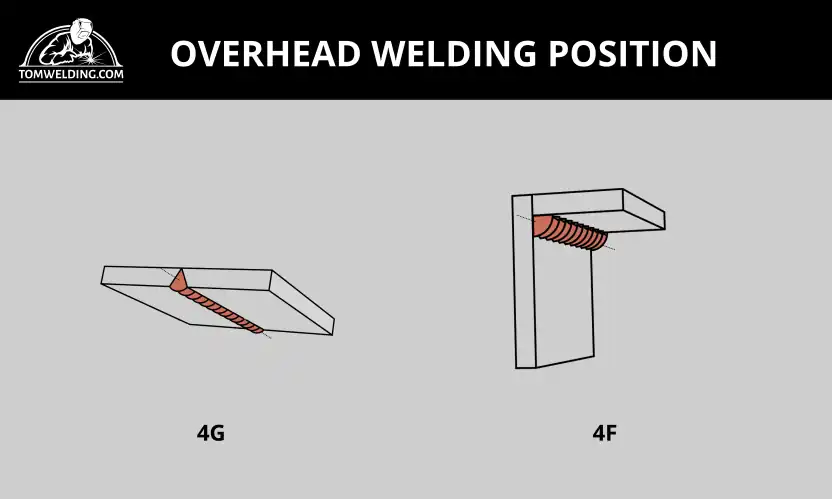

You also need to learn about welding types, because it’s will help you choose the most suitable method for your projects and ensure the highest quality results

When you’re ready to start welding, practice your technique on scrap pieces before moving on to actual projects. Develop a steady hand, learn to control your heat input, and pay attention to the quality of your welds.

As a new welder, it’s essential to build a strong foundation in both knowledge and technique. Here are some tips to help you get started on the right foot

- Invest in proper training: Enroll in a welding course, join an apprenticeship program, or seek out a mentor to learn the basics and gain hands-on experience. Make sure to practice as much as possible to refine your skills.

- Learn about materials: Understand the different types of metals, their properties, and how they react to heat. This knowledge will help you choose the right welding process, filler materials, and techniques for each job.

- Safety first: Always wear appropriate personal protective equipment (PPE) such as a welding helmet, gloves, safety glasses, and flame-resistant clothing. Ensure your work area is well-ventilated and free of flammable materials. Familiarize yourself with safety procedures and guidelines in your workplace.

- Master the basics: Get comfortable with the essential welding processes like SMAW, GMAW, GTAW, and FCAW. Practice proper joint preparation, including cleaning and beveling, to achieve strong, durable welds.

- Develop proper technique: Focus on maintaining a steady hand, controlling your heat input, and monitoring travel speed. Pay attention to the quality of your welds and practice maintaining a consistent bead appearance.

- Cleanliness is key: Always clean your workpieces before welding to remove dirt, rust, grease, and other contaminants that could compromise the integrity of your welds.

- Stay organized: Keep your work area clean and well-organized. Organize your tools and equipment, and maintain your welding machine and consumables to ensure optimal performance.

- Be patient: Welding is a skill that takes time and practice to develop. Don’t get discouraged if you don’t see immediate progress. Learn from your mistakes and continue to practice and improve.

- Join a community: Connect with other welders, either in-person or online, to share knowledge, tips, and experiences. Learning from others can be invaluable in your development as a welder.

- Stay up-to-date: The welding industry is always evolving, with new techniques and technologies emerging. Stay informed about the latest advancements and best practices to continue honing your skills and staying competitive in the field.

With time and dedication, you’ll be able to master the various welding processes and become a skilled professional welder. Welcome to the world of welding!

3 thoughts on “Welding Process and Tips for Beginner”