Welcome to the world of welding! As a new welder, it’s essential to familiarize yourself with the different types of welding joints and their applications.

In this article, let’s learn together the various welding joint types and provide insights on when to use each joint during the welding process.

By understanding the characteristics and appropriate applications of each joint type, you’ll be better equipped to create strong, durable connections that meet the requirements of your projects.

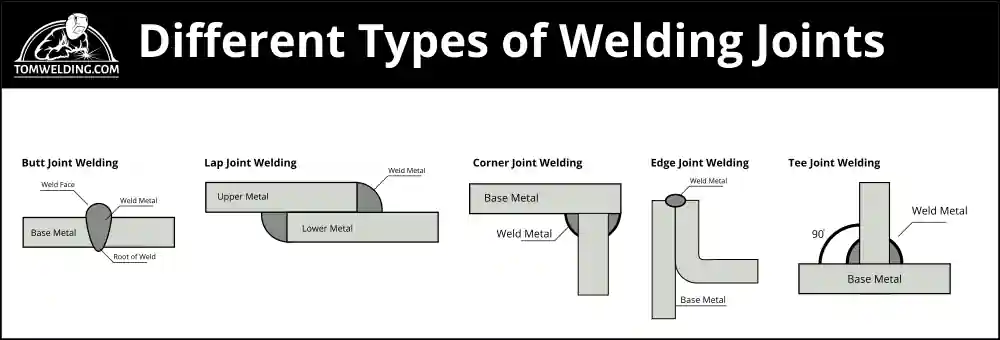

We’ll cover the following welding joint types in this guide:

- Butt Joint: A basic welding joint used when joining two pieces of metal edge-to-edge.

- Corner Joint: A joint employed when joining two pieces of metal at a 90-degree angle, forming a corner.

- T-Joint: A joint that resembles the letter ‘T,’ where one piece is positioned perpendicular to the other.

- Lap Joint: A joint created when two pieces of metal overlap each other and are welded along the edge where they meet.

- Edge Joint: A joint used to join the parallel edges of two metal pieces lying in the same plane.

For each joint type, we’ll discuss its characteristics, the welding process, and the situations in which it’s most commonly used. This guide will help you build a solid foundation in welding and prepare you for a successful career in the field. Let’s dive in!

Butt Joint

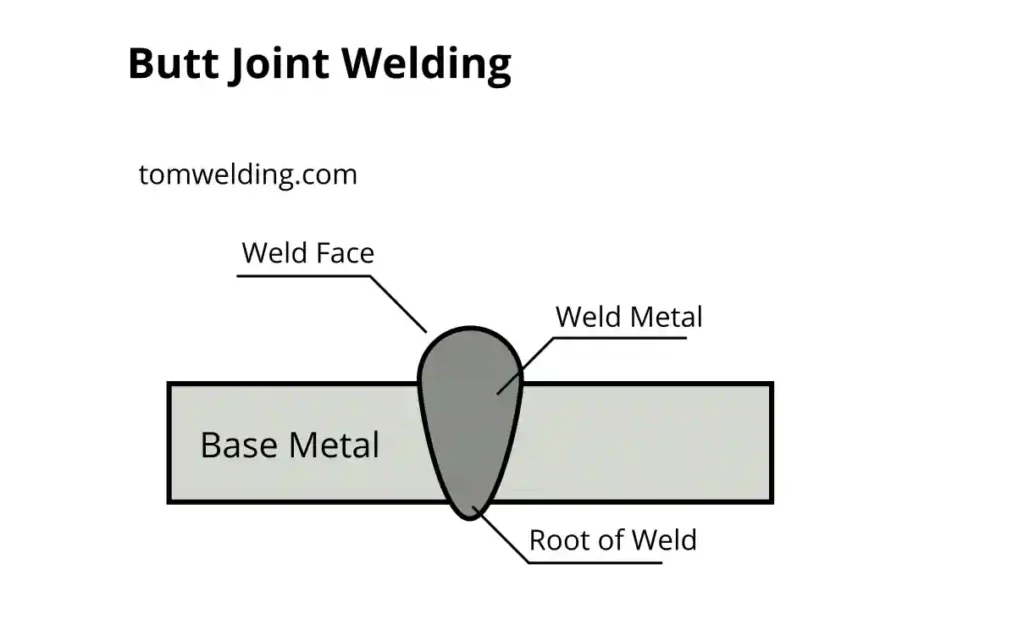

This is the most basic welding joint, where two pieces of metal are joined together edge-to-edge. We use butt joints when the thickness of the materials is similar, and we need to create a straight line.

These joints are common in sheet metal fabrication, pipelines, and structural applications. Make sure the edges are properly aligned before welding to ensure a strong connection.

butt joint, one of the most common types of joints you’ll encounter in the welding industry. When we talk about butt joints, we’re referring to a situation where two pieces of metal are placed together in the same plane, with their sides joined by welding. This joint is frequently used in the fabrication of structures and piping systems, and it’s relatively simple to prepare. There are many different variations that can be applied to achieve the desired result.

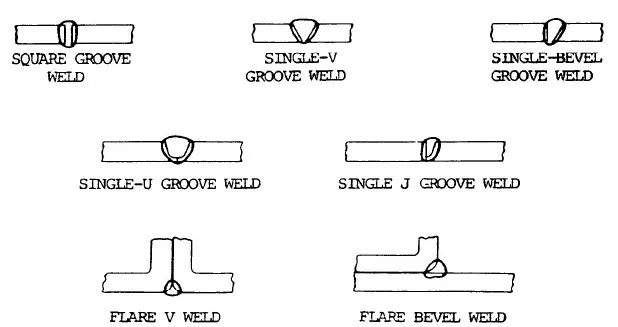

In the world of butt welds, there are several ways to make them, each serving a different purpose. Factors like the shape of the groove, layering, and width of the gap can vary. Here are some typical examples of butt weld joints you might come across:

- Square

- Single bevel

- Double bevel

- Single J

- Double J

- Single V

- Double V

- Single U

- Double U grooves

The part of the metal’s surface that gets melted during the welding process is called the faying surface. To increase the weld’s strength, we can shape the faying surface before welding, a process known as edge preparation. The edge preparation may be the same on both members of the butt joint, or each side can be shaped differently.

There are several reasons why we prepare the faying surfaces for welding, including:

- Adherence to codes and standards

- Adaptation to different metals

- Deeper weld penetration

- Smooth appearance

- Increased strength

In some cases, the exact size, shape, and angle of a groove can be specified. If exact dimensions aren’t given, the groove can be made to the necessary size. However, it’s essential to remember that the wider the groove, the more welding it will require to complete.

As the metal becomes thicker, we must change the joint design to ensure a sound weld. On thin sections, it’s often possible to make full penetration welds using a square butt joint. When welding on a thick plate or pipe, it’s often impossible to achieve 100% penetration without some type of groove being used.

It’s important to be aware of common defects that can occur with butt joints, such as burnthrough, porosity, cracking, or incomplete penetration. By modifying the welding variables, we can avoid these issues and ensure a high-quality weld.

Example: Butt joints are frequently used in automotive body repair when replacing a damaged section of a car panel. The damaged part is cut out, and a new piece is fitted edge-to-edge with the existing panel, then welded to create a seamless repair.

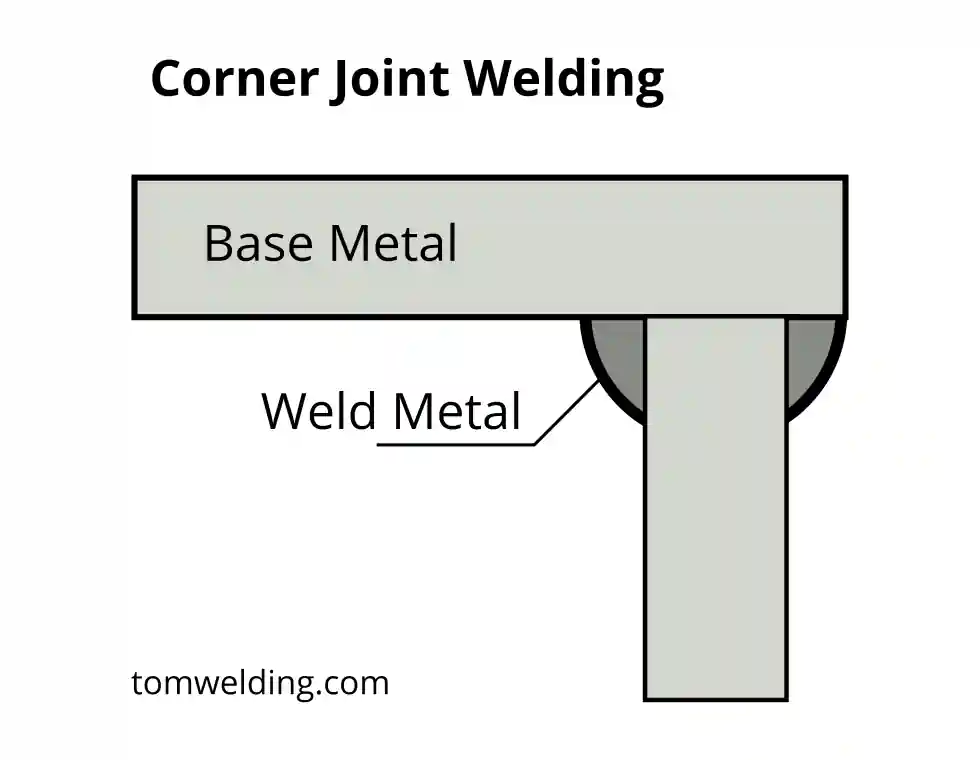

Corner Joint

A corner joint is used when two pieces of metal are joined together at a 90-degree angle, forming a corner. You’ll often find these joints in frames, boxes, and other structures that require right angles. It’s important to maintain a steady hand and ensure that the angle is precise when welding a corner joint.

These types of joints are among the most common in the sheet metal industry, found in the construction of frames, boxes, and other applications. There are two ways of fitting up an outside corner joint—either forming a V-groove (A) or forming a square butt joint (B), as seen in the diagram below.

When it comes to creating corner joints, there are several styles to choose from, including:

- V-groove

- J-groove

- U-groove

- Spot

- Edge

- Fillet

- Corner-flange

- Bevel-groove

- Flare-V-groove

- Square-groove or butt

As a welder, understanding the differences between tee joints and corner joints, as well as the various styles used for creating them, is crucial when working in the sheet metal industry or on projects that involve frames, boxes, and similar structures.

Example: Corner joints are often used in the construction of metal cabinets or shelving units, where the side panels and the back panel meet at a 90-degree angle to form a sturdy structure.

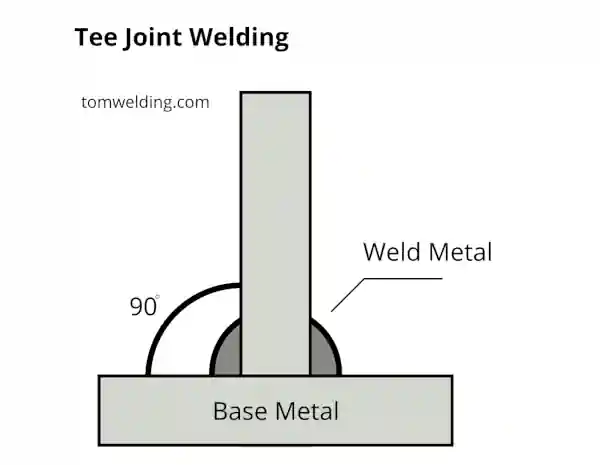

Tee-Joint

Tee joints, which are formed when two pieces intersect at a 90-degree angle. This configuration results in the edges coming together in the center of a plate or component, creating a ‘T’ shape. Tee joints are considered a type of fillet weld, and they can also be created when a tube or pipe is welded onto a base plate.

With tee joints, it’s crucial to ensure there’s effective penetration into the roof of the weld. There are several welding styles that can be used to create a tee joint, including:

- Plug weld

- Slot weld

- Bevel-groove weld

- Fillet weld

- J-groove weld

- Melt-through weld

- Flare-bevel-groove weld

Typically, tee joints don’t require groove preparation unless the base metal is thick and welding on both sides can’t withstand the load the joint must support.

One common defect that can occur with tee joints is lamellar tearing, which happens due to the restriction experienced by the joint. To prevent this, we welders often place a stopper to avoid joint deformities.

Example: T-joints are commonly used in the fabrication of metal tables or workbenches, where the vertical legs are joined to the horizontal tabletop or support beams, creating a 90-degree angle between the two pieces.

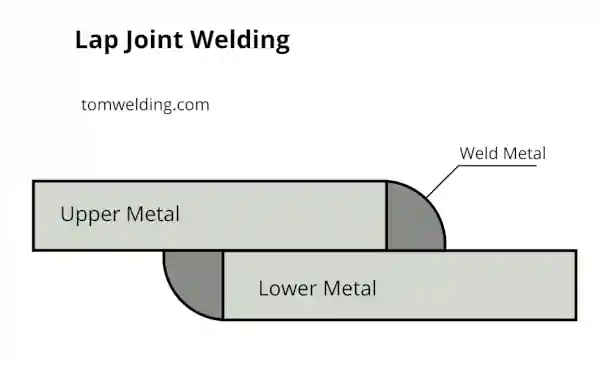

Lap Joint

A lap joint is created when two pieces of metal overlap each other and are welded along the edge where they meet. This joint is commonly used when joining two pieces of material with different thicknesses or when adding reinforcement to a structure. Be mindful of achieving the right balance between penetration and heat distribution to avoid distortion.

Example: Lap joints are often used in the assembly of metal storage racks or shelves, where the horizontal shelf is overlapped and welded onto the vertical support beams, providing added strength and stability.

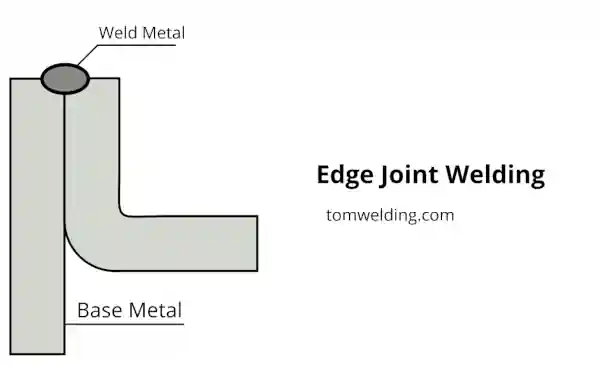

Edge Joint

An edge joint is used to join the parallel edges of two metal pieces that are lying in the same plane. The weld is typically placed along the seam where the edges meet. Edge joints are less common than the other types and usually serve as a temporary joint before further fabrication. Ensure proper edge preparation and alignment to achieve a strong bond.

Example: Edge joints may be used in the fabrication of large metal sheets or panels when the required dimensions exceed the available material size. Two pieces of metal are placed edge-to-edge and welded along the seam to create a single, larger piece.

As you gain experience in welding, you’ll become more comfortable with these joint types and learn the best techniques to create strong, durable connections. Remember, practice makes perfect! Good luck on your welding journey!

Ref: Wikipedia

2 thoughts on “Understanding Welding Joint Types and Their Applications”